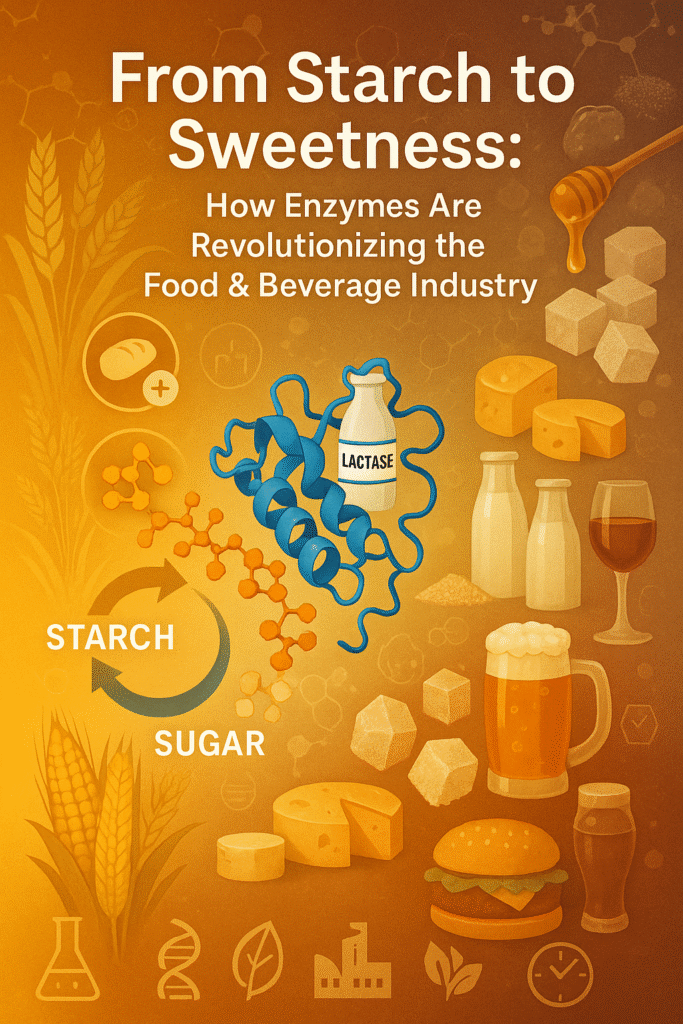

Enzymes, nature’s powerful biological catalysts, are transforming the way we produce food and beverages. Already present in many everyday products, these natural workhorses are now driving innovation in industrial food processing. By enhancing efficiency, improving quality, and enabling healthier, more sustainable products, enzymes are becoming indispensable in the industry.

With growing demand for clean-label foods, reduced waste, and enhanced nutrition, enzyme-based processing is on the rise. This article explores how enzyme technology is reshaping the food and beverage sector—from starch conversion and dairy processing to brewing, baking, and beyond.

Table of Contents

- The Role of Enzymes in the Food & Beverage Industry

- Enzymes in Starch Conversion & Sweetener Production

- Dairy Industry: Enhancing Quality & Digestibility

- Brewing & Beverages: Boosting Flavor & Efficiency

- Baking & Milling: Improving Texture & Shelf Life

- Meat & Plant-Based Processing: Tenderization & Innovation

- Future Trends: The Next Wave of Enzyme Technology

1. The Role of Enzymes in the Food & Beverage Industry

What Are Enzymes and How Do They Work?

Enzymes are specialized proteins that accelerate biochemical reactions without being consumed in the process. In food production, they break down complex molecules into simpler ones, improving digestibility, texture, and flavor. Unlike harsh chemical methods, enzymes operate with precision, efficiency, and environmental friendliness, making them ideal for modern food processing.

Why Enzymes Are Game-Changers

- Enhanced Quality: Improve texture, taste, and nutritional value.

- Efficiency: Reduce processing time and energy consumption.

- Clean-Label Appeal: Replace synthetic additives with natural solutions.

- Sustainability: Minimize waste and lower carbon footprints.

As consumer demand grows for healthier, minimally processed foods, enzymes are paving the way for smarter, greener production.

2. Enzymes in Starch Conversion & Sweetener Production

Breaking Down Starch for Sweeteners

Enzymes like amylase and glucoamylase convert starch into fermentable sugars, essential for sweeteners such as high-fructose corn syrup (HFCS). Additional enzymes like pullulanase and isoamylase optimize the process, ensuring higher yields and better-quality sweeteners.

Crafting Healthier Sweeteners

- Glucose isomerase transforms glucose into fructose, a key step in HFCS production.

- Enzymes also help create alternative sweeteners like maltodextrins, offering reduced-calorie options without artificial additives.

This enzymatic approach enables the production of natural, better-tasting sweeteners while meeting clean-label demands.

3. Dairy Industry: Enhancing Quality & Digestibility

Lactose-Free Dairy with Lactase

Lactase breaks down lactose into glucose and galactose, making dairy products digestible for lactose-intolerant consumers. The rising popularity of lactose-free milk, yogurt, and cheese highlights the importance of enzymes in dairy innovation.

Cheese Production & Flavor Enhancement

- Rennet and microbial proteases curdle milk proteins, crucial for cheese-making.

- Lipases develop rich, complex flavors in aged cheeses.

Enzymes also improve milk protein digestibility, reducing allergenic properties for sensitive consumers.

4. Brewing & Beverages: Boosting Flavor & Efficiency

Beer & Alcohol Production

- Amylases and proteases convert starches into fermentable sugars, optimizing alcohol yield.

- Beta-glucanase improves beer filtration and mouthfeel.

Juice & Soft Drink Processing

- Pectinase clarifies juices, enhancing transparency and stability.

- Cellulases increase juice yield and reduce viscosity.

Wine & Spirit Refinement

- Glucosidases enhance aromatic profiles in wines.

- Tannase softens tannins, creating smoother spirits.

Enzymes ensure consistent quality, better flavor, and higher efficiency across beverages.

5. Baking & Milling: Improving Texture & Shelf Life

Dough Enhancement & Bread Quality

- Amylases improve fermentation and crumb structure.

- Xylanases increase dough elasticity.

- Proteases modify gluten for specialty baked goods.

Extending Freshness

- Lipases prevent fat oxidation.

- Anti-staling enzymes slow bread hardening, reducing food waste.

Enzymes help bakers achieve superior texture, volume, and longevity in products.

6. Meat & Plant-Based Processing

Meat Tenderization

- Proteases break down tough protein fibers, enhancing tenderness and juiciness.

- Enzymes improve marination and flavor absorption.

Plant-Based Innovations

- Transglutaminase binds proteins in meat alternatives, improving texture.

- Proteases enhance flavor and digestibility in plant-based cheeses and dairy substitutes.

Enzymes are key to developing realistic, high-quality meat alternatives.

7. Future Trends: The Next Wave of Enzyme Technology

Advanced Enzyme Engineering

- Precision fermentation enables customized enzyme production.

- Genetic modification enhances enzyme efficiency and functionality.

Sustainability & Waste Reduction

- Enzymes lower energy and water use in food processing.

- They convert byproducts into valuable ingredients, reducing waste.

Personalized Nutrition

- Enzyme-enhanced foods cater to individual dietary needs.

- Functional foods with targeted health benefits are on the rise.

Conclusion

Enzymes are revolutionizing the food and beverage industry by enabling cleaner, more efficient, and sustainable production. From starch conversion and dairy processing to brewing, baking, and plant-based innovations, enzyme technology is driving the future of food.

As research advances, we can expect even more breakthroughs—ushering in an era of smarter, healthier, and eco-friendly food solutions. The enzyme revolution is here, and it’s transforming what we eat and drink for the better.